For CIC the concept of a connected worker is much more complex than just giving someone some mobility tools to carry out their work.

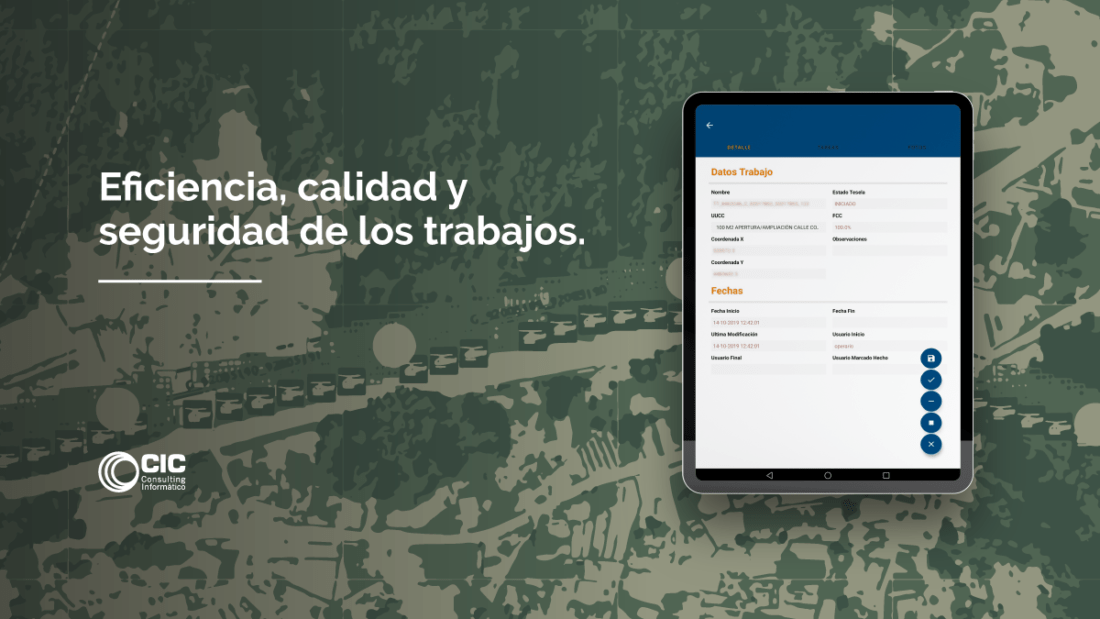

The term has a much wider meaning for us, from detecting the need for the actual work being done in the field to concluding that job, once the information has been completed and the job has finished. As for technological solutions, at CIC Consulting Informático we contemplate everything, from aspects that help increase efficiency, quality and operational security, such as collaborative tools, which substantially changes relations of those involved in the process.

The connected worker and the decision making process: more accurate, intelligent and quicker.

The objective of the connected worker must be to increase efficiency, quality and security in his work. It is clear that to reach this objective it is necessary to equip the user with new tools that need to be used in the process, from planning resources to those who will use the tools. But to attain these objectives, the new tools have to be fully integrated, not only from an ergonomic perspective, but data has to be accessible, so that his work can be carried out.

In this sense, these concepts must not only determine the technological viability of the tools but how they are expected to be used. They also have to gather the experiences and opinions of the end users; how easy was it to use? What aspects could be improved? What is the end goal?

Access to data improves efficiency, quality and security

Some recommendations to better the new tool are easy to adopt. However, access to data is the key for a better tool, because it increases efficiency, quality and security.

Nevertheless, data has to be available at the right moment and precise place, and it is here where some modifications might be necessary.

An example of this is in the utilities sector, where many companies want to incorporate sensors in personal protective equipment that operators must use to work.

To register personal protective equipment is quite a feat in itself. If we combine it with the information where the worker is going to be working, the type of job he will be doing and his position, we have added a preventive capacity solution, producing more information, which helps the worker and the company.

CIC Consulting Informático has worked with the most relevant companies in the Spanish utilities sector, transforming their felling and pruning work. This has meant a 30% savings in income, not to mention other benefits.

The methodology used has optimized felling and pruning plans according to algorithms based on internal and external data: LiDAR flights, installations, type of vegetation, orographyand climatology.

The solutions developed by CIC allow for automatic felling and pruning settings. Each setting is evaluated on available resources, cost and risk.

As a consequence, the work of the planners is transformed, focused on the analysis of the results and development of a new setting proposal. Part of this information came from work orders; others, took into account the type of vegetation, what and where work had to be done. All information is important when programming orders.

Development of tools that allow access to available information

As a consequence, the work of the planners is transformed, focused on the analysis of the results and development of a new setting proposal. Part of this information came from work orders; others, took into account the type of vegetation, what and where work had to be done. All information is important when programming orders.

All this information is very valuable when the work is being prepared, it allows for work to be grouped by risk, opportunity, proximity and other factors.

Finally, the capacity for ubiquitous access to information, combined with collaborative tools, permits a redefinition of work procedures and decision making.

Changes that translate into great benefits

The new procedures will inevitably change the roles and functions of administrators, technicians, supervisors and operators. The materializations of the new way of working will require training and an effective management change at all levels.

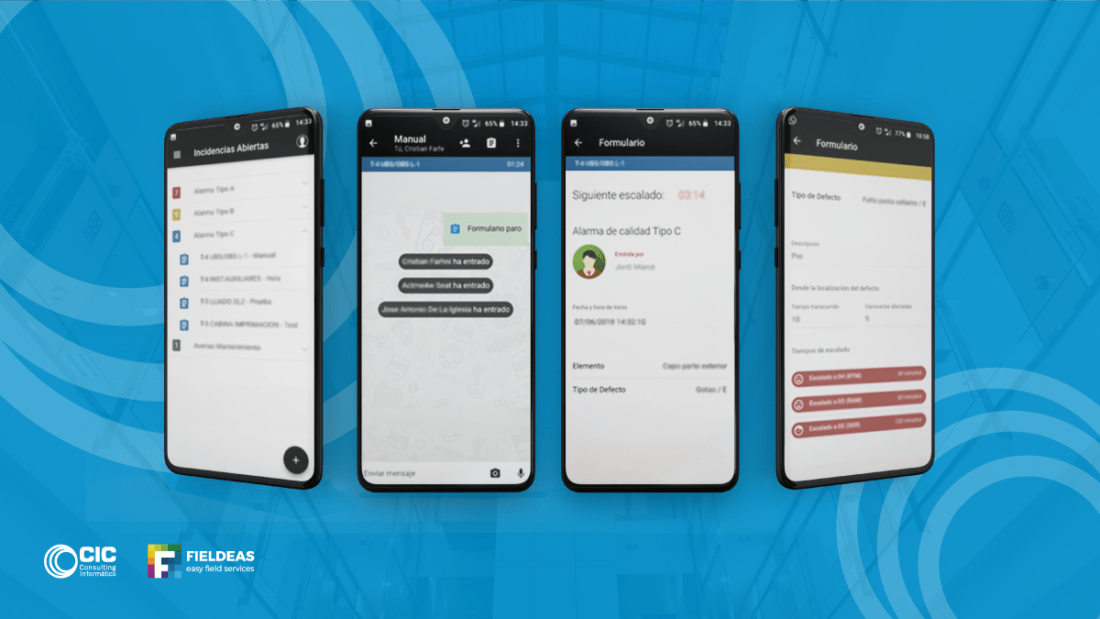

This way, in an automobile manufacturer, we would install a FIELDEAS mobility solution, integrate it with a collaborative tool to make things more agile; a 20% reduction, in average time, for resolution of incident management issue would be the result.

A collaborative tool would make ubiquitous access to information of an incident and the participation of all the actors in the diagnosis and resolution of the incident. It also systemizes the approval flows and closure of the work.