What is industry 4.0 and why is it important?

Industry 4.0 is another term for the fourth industrial revolution in manufacturing. It’s a digital transformation in the industrial sector that includes automation, data exchange, cloud computing, robotics, Big Data, Artificial Intelligence, IoT and technological trends; all used to achieve industrial objectives and intelligent manufacturing practices that interact with people, new technologies and innovation. Without going any further, the concept of Industry 4.0 is the introduction of digital technologies in manufacturing processes.

The digital transformation has become very important, it is now responsible for changing industry and adapting it to a connected industry. It is a process that requires great personal awareness and unifies all parts of a company. Today, industrial manufacturing companies are using advanced technologies that are moving from mass production to a more personalized production.

Consumer’s expectations have changed due to the arrival of portable devices and connected platforms. This situation is what takes the new connected industry 4.0 to digitalization. Industries continue their evolution, in response to the challenge of guaranteeing that their products arrive correctly, at a good price, to the correct client; it is a very complex process.

The advantages of Industry 4.0 or the intelligent factory

Intelligent factories have become very important; the industrial sector has been greatly affected by the digital transformation. Industrial enterprises were once on the margin of digitalization and IT.

Today, however, there are intelligent factories offering great advantages through the digitalization of industrial processes:

- The great quantity of connected data allows for a more personalized approach, as well as acquiring a very broad capacity to adapt to demand.

- Production processes have been purged, repetitive, error free, which allows for 24 hour production capacity

- All automated manufacturing processes are more precise. Downtimes are avoided.

- An important increase in design and production of the product. Shorter production times.

- Increased sales.

- Exhaustive controls means greater efficiency, which means we obtain greater cost savings

- Automated processes require less personnel, less errors and greater energy efficiency, raw materials, etc…

Advantages of intelligent factories in a connected industry have these basic characteristics:

- Automation

- Data connectivity

- Availability of digital information in much less time

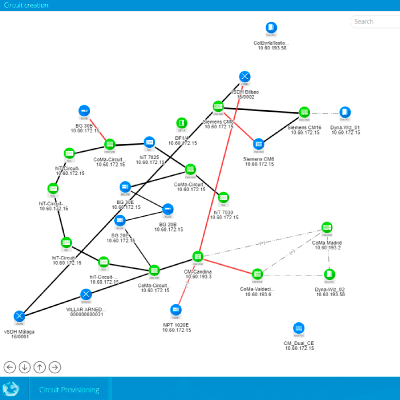

CIC provides a technology based on compatibility standards and guarantees a future projection.

IoT and connected industry 4.0

At the epicenter of this new industrial revolution is the Internet of Things (IoT) and it is key to industries as it affords them an economic advantage.

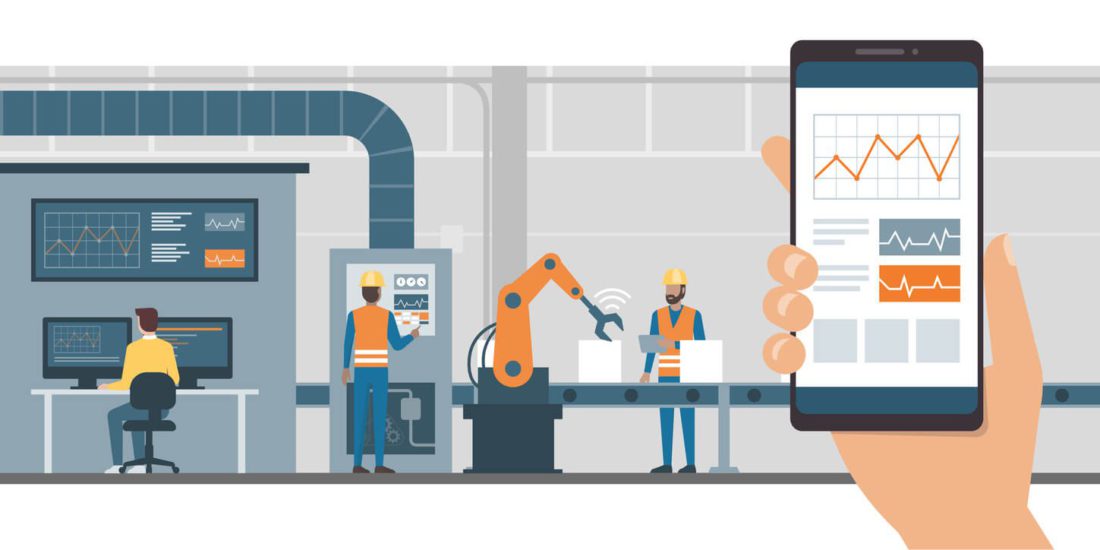

In Industry 4.0, the idea is to do things differently: Introduce automation and the exchange of data in the manufacturing process. The industries that have adapted to Industry 4.0 are leaders in their field due to the revolutionary ways that this new connected technology has simplified production processes. For example, IoT can provide you with an overview of everything that is happening in the factory, building, company… in real time, as well as alarms and damaged goods. These implementations, simple but critical, reduce costs and waste.

We are, therefore, talking about connected industry 4.0 as we incorporate more IoT. “It represents a vision of an interconnected factory where the equipment is in line, and in some sort of way, is intelligent and capable to take its own decisions”.

The tendency to massive personalization has allowed manufacturers to react in a more efficient way to consumer demand. As clients want the products they use to be intuitive and easy to interact with, mobilization and connectivity force manufacturers to innovate faster and create products for software. The capacities of IoT and Industry 4.0 are also changing the way after-sales service is being handled; today, there is immediate and 24 hour support.

At CIC we guide you towards a connected industry by offering software solutions for the industrial sector customized for each business

Artificial Intelligence (AI) and Automatic Learning

The ability for a machine to learn and adopt intelligent human behaviour is a new advance. In reality, algorithms have advanced, and are transforming the way that industry gathers information, carries out work with authority and predicts what consumer behaviour will be. Intelligent factories with integrated Automatic Learning have shown a 20% rise in production capacity.

The industrial transformation has created a situation where quality has not been sacrificed for efficiency. This is due to the algorithms used in automatic learning. They take into account different factors, impacts and production quality. Sensors have replaced human hands, which means less time and materials, as well as more precision and an optimal workflow. The digitization of industry (connected industry 4.0) implies lower production costs, quicker delivery times and better response to client demands

The industrial transformation increases speed and efficiency

Automated technologies are essential for speed and efficiency, allowing companies to optimize production workflows, inventories, works in progress and decisions. Adding CIT systems, the different teams in different geographic locations can access relevant data, making communication faster, collaborative and transparent, making the data in the cloud more stable.

Industry 4.0 has achieved predictive precision thanks to better monitoring processes, which means a higher performance level much superior to what it had been before it was connected. The industrial transformation and the connected technology associated with it, allows employees to be able to have a continuous data flow, which affords them faster decisions and consequently quicker action.

Better speed and efficiency means less costs and better quality control in industrial processes.

Data and analysis – Big Data in Industry 4.0

It is predicted that by 2020, there will be 50 times more digital content than there is today. Big Data analysis is more and more difficult: The digital manufacturer has more difficulty administering, updating and analysing information regarding products and consumers. Therefore, many companies have decided to move their data to the cloud, as well as having a place to store, administer and process on the ground.

The 4th Industrial Revolution is different, in that it manages huge amounts of data that the industry is exposed to. The way they use this information is the most important factor in order to get a competitive advantage and a better final product to the client. At the same time the company is more efficient and effective.

How to improve environmental impacts in the industrial transformation 4.0

Energy efficiency has become a new competitive factor in the transformation of industry. Energy use is a key element in the change of the productive model through energy saving technologies.

It’s an economic model that begins with innovations in energy. The market will develop new technological products that will compete in a market with a lower energy demand; this will become a structural phenomenon.

Intelligent technologies lead us to an Industry 4.0 model with new production techniques in the energy sector and CITs. The production of efficient products aimed at the new market require lower energy costs and to satisfy a new type of customer that is environmentally conscious.

This new paradigm would not make any sense if the systems were implanted individually, working independently, but, instead, with a common goal and integrated with one and other.